The Problem: Pedal spindle threads are very often hard to move at first when a pedal needs to be unscrewed from a crank-arm. On the other hand a pedal needs to be tightened snugly when it's being installed.

People have various ways of preventing the whole crank-set from turning when pressure needs to be applied to a pedal wrench. You can reach through the frame and grasp the opposite crank-arm with one hand while using the pedal wrench on the closer pedal with the other hand. As your finely conditioned and muscular arms tense against each other the wrench will often slip resulting in lacerated knuckles.

I've seen the opposite crank-arm lashed to the chain-stay with a spare toe strap which may not be good for the chain-stay or the strap. And it's useless if you don't use toe-clips and have no straps.

You can put a foot tall block under the opposite crank-arm when it's horizontal which always means that you must hold the bike down while pulling up on the pedal wrench.

Full time professional mechanics seem to manage it with no more than their two arms, a wrench and long practice but it's the amateurs can often use a little help.

My Solution: It is inspired by a veteran mountain biker I knew who had an eight inch tall stub of stout hardwood fencepost with a slot cut into it sticking out of the ground outside his workshop.

|

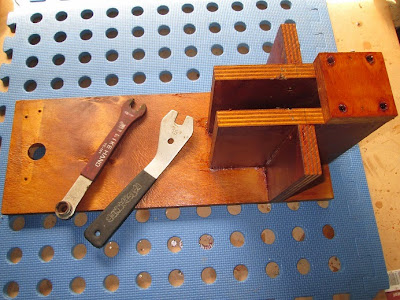

| Fairly good pedal wrench (left) Better pedal wrench (right) |

It hangs on a nail when not in use and makes a handy place to drape inner tubes under repair while the patch glue is drying.

|

| In place on the drive side |

|

| Stand on it with both feet |

That's about it really. The wooden jaws won't mar the crank arms but if you are fastidious you can always pad them with shop rags. And make sure you have a properly fitting and substantial pedal wrench.